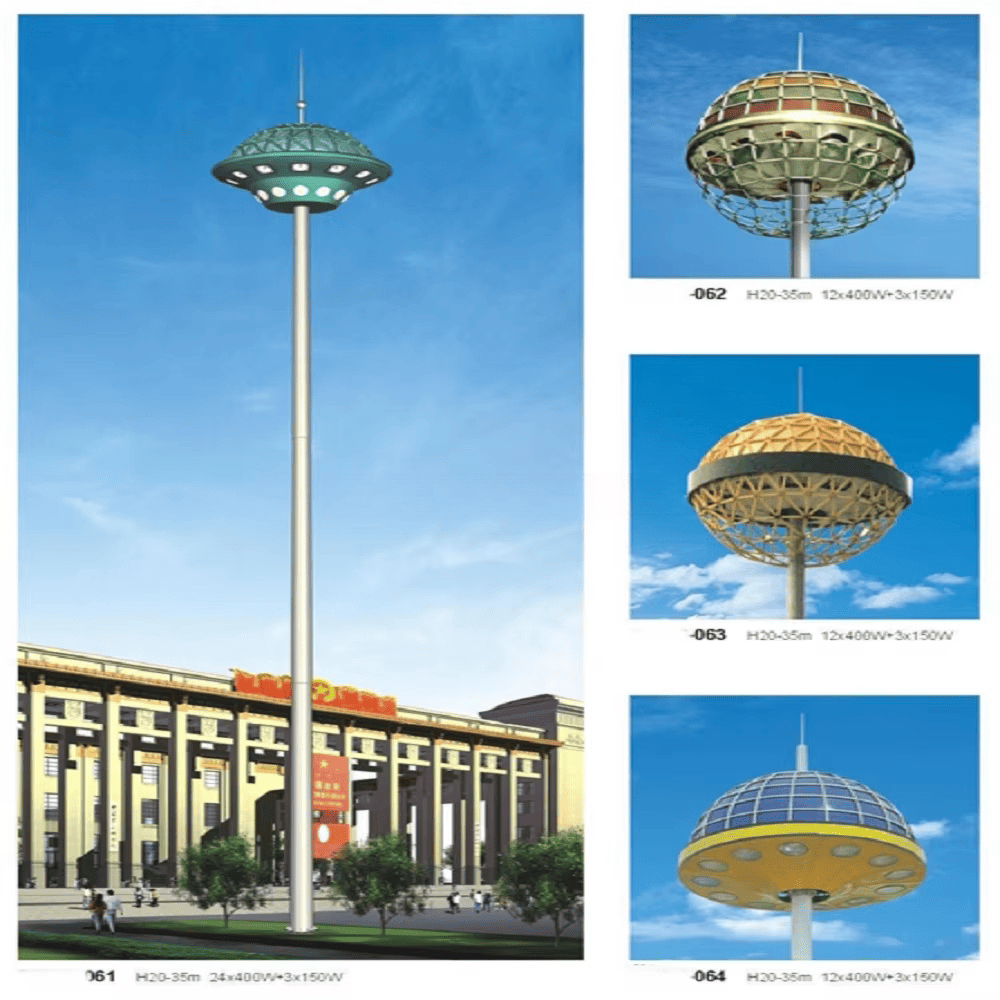

high mast led manufacturer

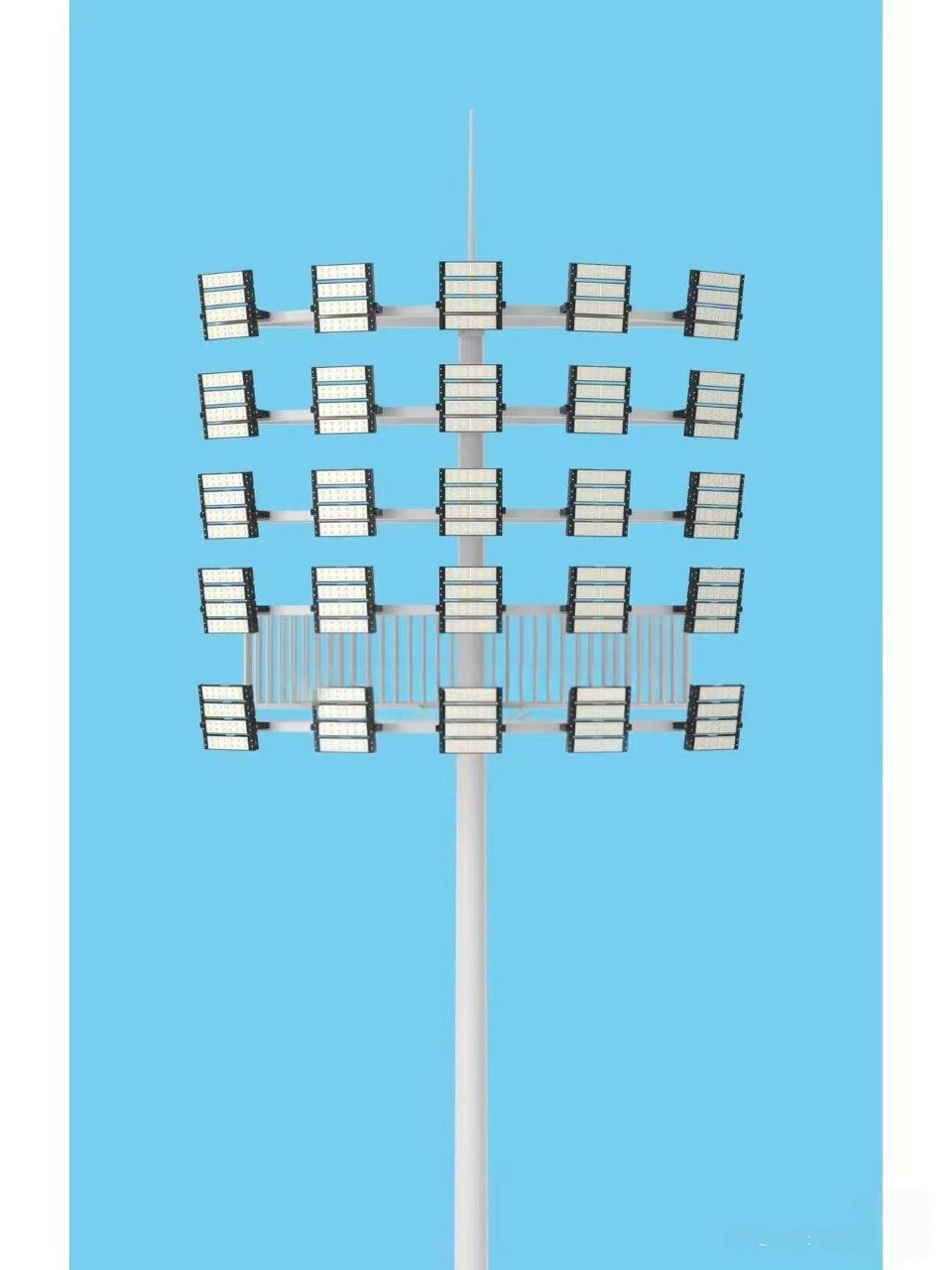

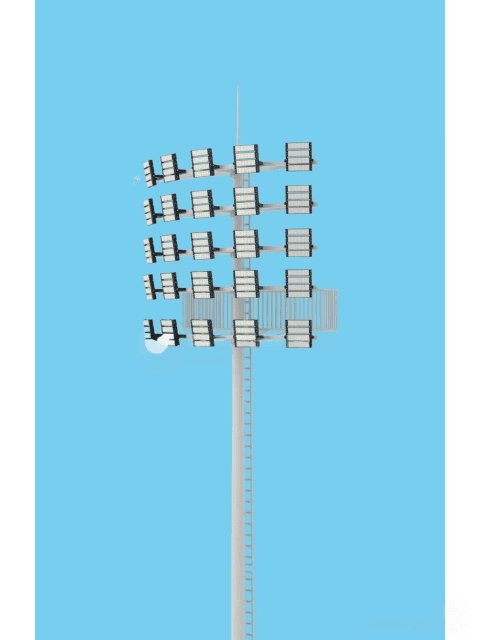

A high mast led manufacturer represents a specialized industrial entity focused on producing advanced lighting solutions designed for large-scale illumination applications. These manufacturers concentrate on developing robust LED lighting systems specifically engineered for mounting on tall poles, typically ranging from 15 to 60 meters in height. The primary function of a high mast led manufacturer involves designing, engineering, and producing powerful LED luminaires capable of delivering extensive light coverage across vast areas such as airports, seaports, highways, industrial complexes, and sports facilities. These manufacturers utilize cutting-edge LED technology, incorporating premium semiconductor chips, precision optics, and thermal management systems to create lighting fixtures that deliver exceptional performance and longevity. The technological features employed by a high mast led manufacturer include advanced heat dissipation mechanisms, weatherproof enclosures rated for harsh environmental conditions, intelligent control systems supporting remote monitoring and dimming capabilities, and modular designs enabling flexible configuration options. Modern high mast led manufacturer facilities integrate sophisticated manufacturing processes, including automated assembly lines, precision optical alignment equipment, and comprehensive quality testing protocols to ensure consistent product reliability. The applications served by a high mast led manufacturer span diverse sectors including transportation infrastructure, where these lighting solutions illuminate major highways, intersections, and parking facilities. Industrial applications encompass manufacturing plants, oil refineries, chemical facilities, and logistics centers requiring extensive nighttime visibility. Commercial applications include shopping centers, recreational facilities, and outdoor event venues. Municipal applications cover public spaces, parks, and emergency response areas. A reputable high mast led manufacturer typically offers customization services, allowing clients to specify luminous flux requirements, beam angle configurations, color temperature preferences, and control system integration. These manufacturers also provide comprehensive support services including installation guidance, maintenance protocols, and warranty coverage, establishing long-term partnerships with clients across various industries seeking reliable, energy-efficient lighting solutions for their large-scale illumination requirements.