high mast led lighting manufacturer

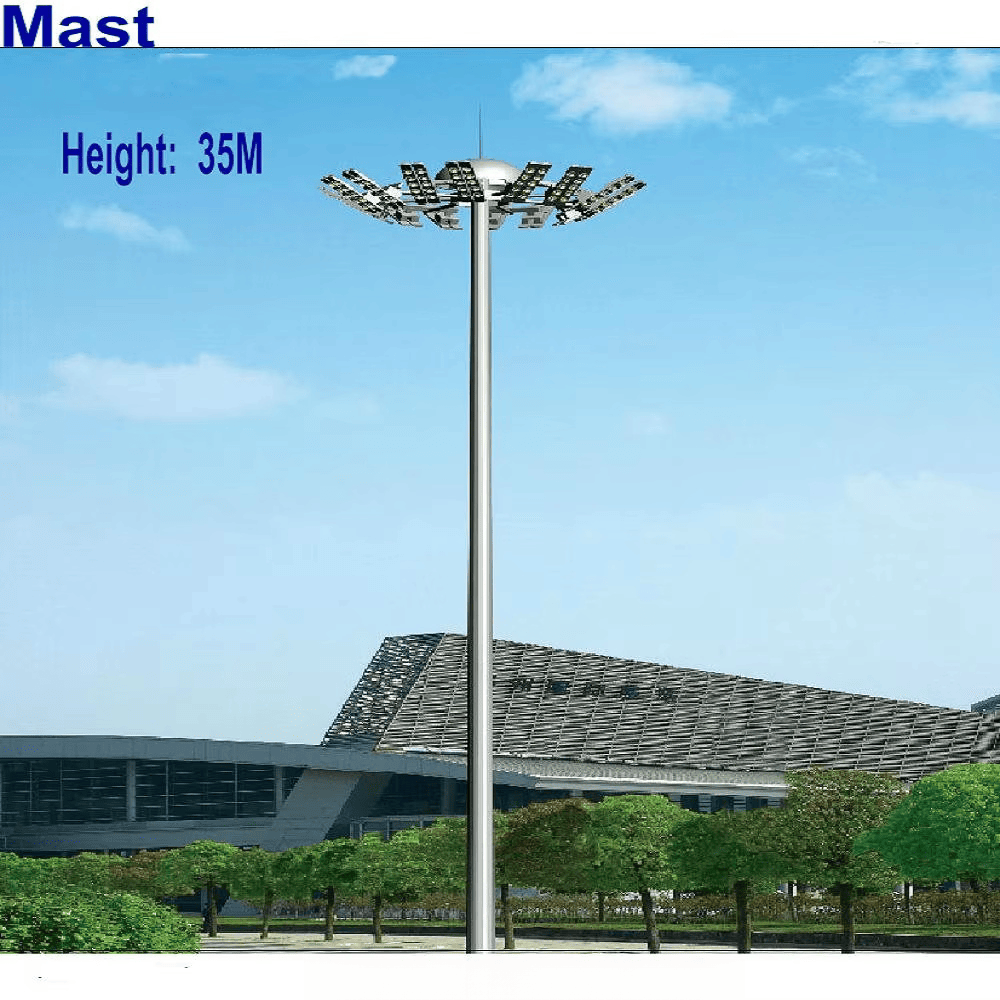

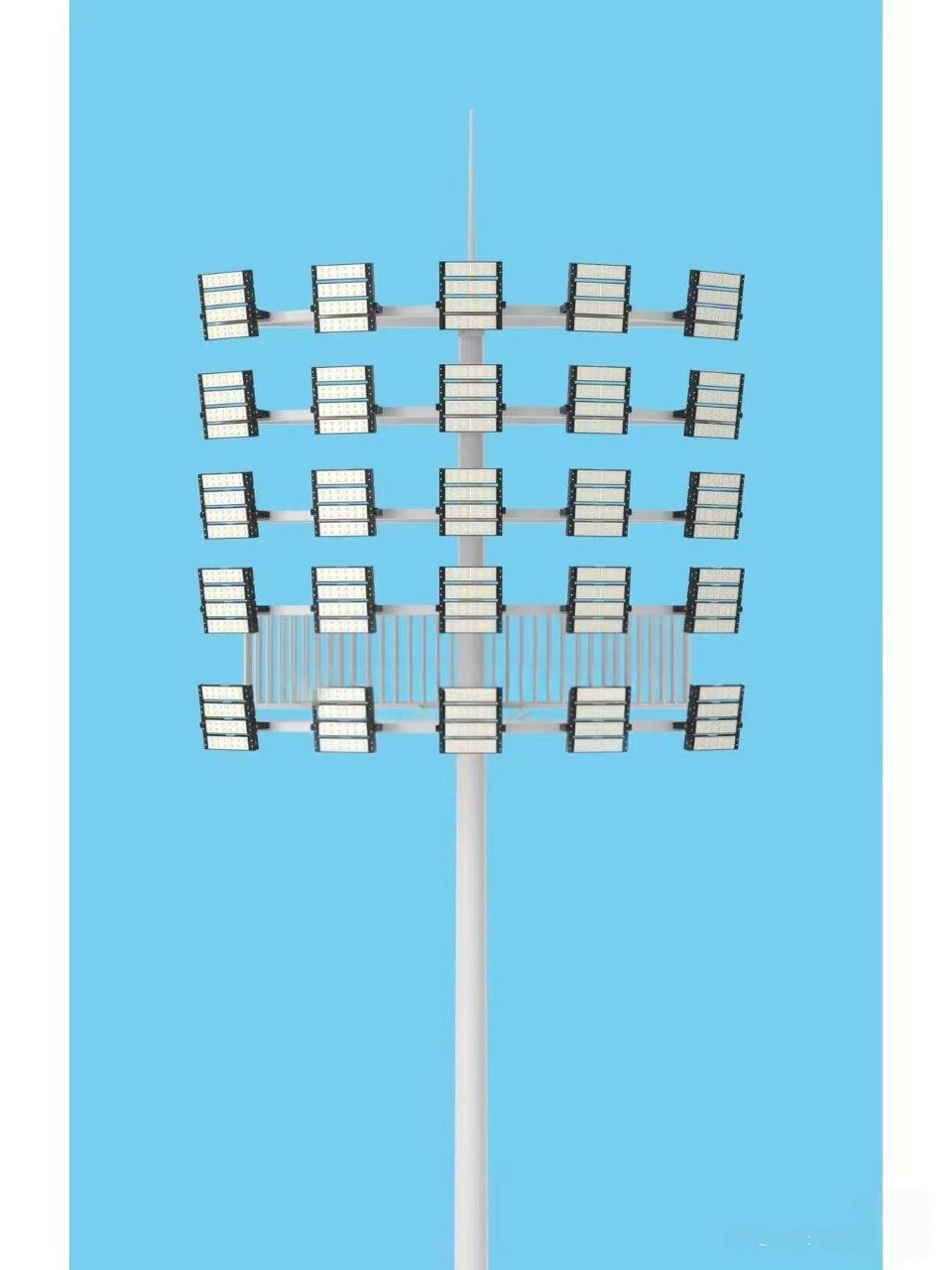

A high mast led lighting manufacturer represents a specialized industrial company dedicated to producing advanced illumination solutions designed for large-scale outdoor applications. These manufacturers focus on creating powerful LED lighting systems specifically engineered for installation on tall poles, typically ranging from 15 to 60 meters in height, serving expansive areas that require comprehensive lighting coverage. The primary function of these manufacturers involves designing, engineering, and producing sophisticated lighting fixtures that combine cutting-edge LED technology with robust mechanical systems capable of withstanding harsh environmental conditions. High mast led lighting manufacturer operations encompass multiple technological features that set them apart from conventional lighting producers. Their products incorporate advanced LED chip technology, featuring high-efficiency diodes that deliver superior luminous output while maintaining exceptional energy efficiency ratios. These manufacturers integrate intelligent control systems, including wireless monitoring capabilities, automated dimming functions, and remote diagnostic tools that enable facility managers to optimize lighting performance and reduce operational costs. The manufacturing process involves precision engineering of heat management systems, utilizing advanced thermal dissipation technologies to ensure LED longevity and consistent performance even in extreme weather conditions. Applications for high mast led lighting manufacturer products span diverse sectors including airports, seaports, highways, industrial facilities, sports complexes, parking lots, and urban infrastructure projects. These lighting solutions prove essential for areas requiring uniform illumination across large spaces, where traditional lighting methods would be insufficient or economically impractical. The manufacturer's expertise extends to customizing lighting solutions based on specific environmental requirements, whether addressing coastal salt exposure, extreme temperatures, or unique mounting challenges that demand specialized engineering approaches.