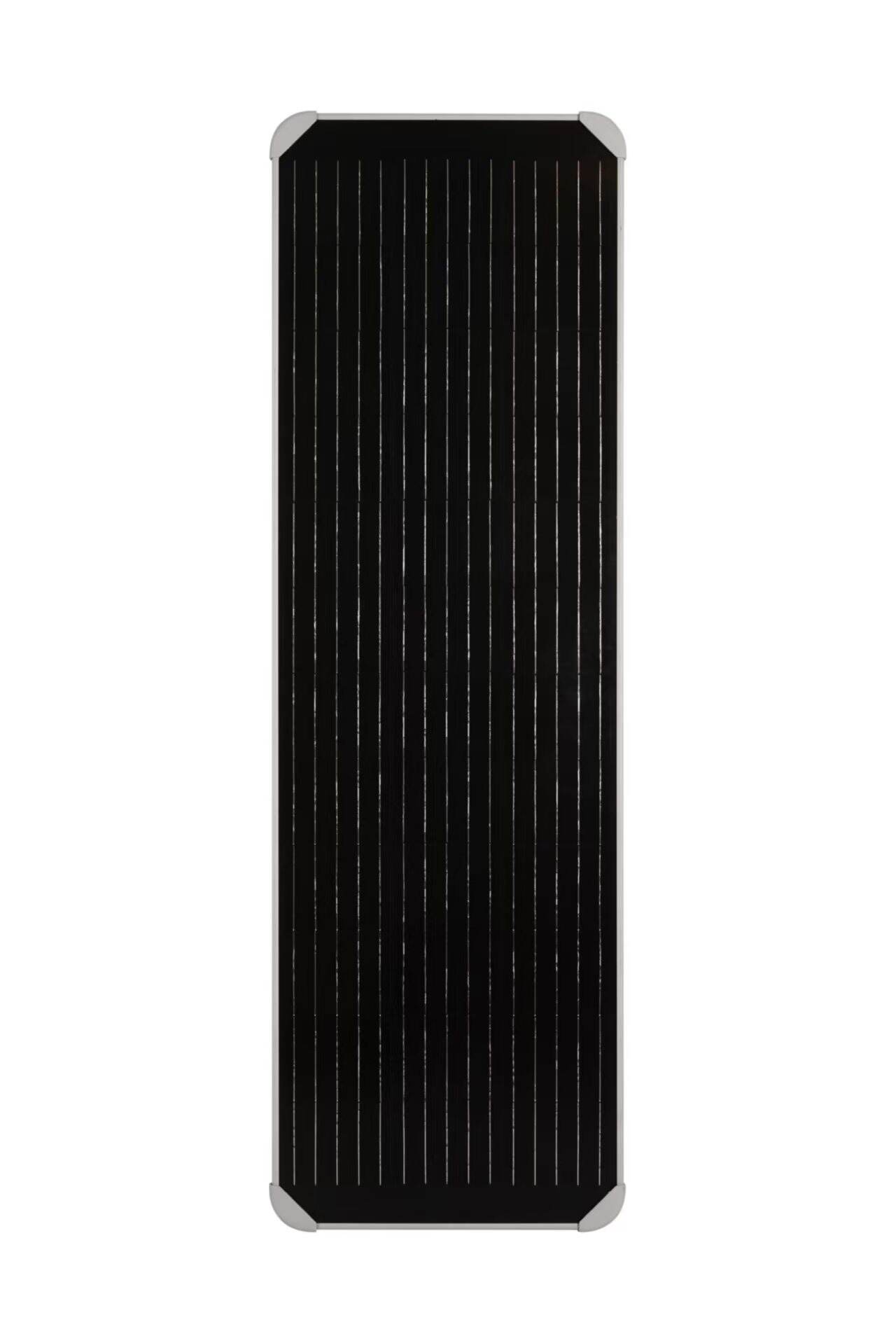

1 steel tubing

1 steel tubing represents a cornerstone of modern industrial infrastructure, offering exceptional versatility and reliability across numerous applications. This premium steel tubing solution combines advanced metallurgical engineering with precise manufacturing processes to deliver superior performance characteristics that meet the demanding requirements of today's industrial environments. The 1 steel tubing features a carefully engineered composition that provides optimal strength-to-weight ratios while maintaining excellent workability and formability. Its main functions encompass structural support, fluid transportation, heat exchange applications, and mechanical component fabrication across diverse industrial sectors. The technological features of 1 steel tubing include enhanced corrosion resistance through specialized surface treatments, precise dimensional tolerances that ensure consistent performance, and superior weldability that facilitates seamless integration into complex systems. Manufacturing processes utilize state-of-the-art cold drawing and hot rolling techniques to achieve exceptional surface finish and dimensional accuracy. The tubing undergoes rigorous quality control testing including tensile strength analysis, pressure testing, and dimensional verification to guarantee compliance with international standards. Applications for 1 steel tubing span automotive manufacturing, construction projects, oil and gas industries, chemical processing facilities, and aerospace components. In automotive applications, this steel tubing serves as exhaust system components, chassis reinforcement elements, and hydraulic line assemblies. Construction projects utilize 1 steel tubing for structural frameworks, handrails, and architectural elements that require both strength and aesthetic appeal. The oil and gas sector relies on this tubing for pipeline systems, drilling equipment, and refinery infrastructure due to its exceptional pressure handling capabilities and chemical resistance. Chemical processing facilities benefit from the tubing's ability to withstand corrosive environments while maintaining structural integrity over extended operational periods. The precise manufacturing tolerances ensure reliable connections and minimize system downtime, making 1 steel tubing an essential component for mission-critical applications where performance and reliability cannot be compromised.