Advanced Composite Material Technology

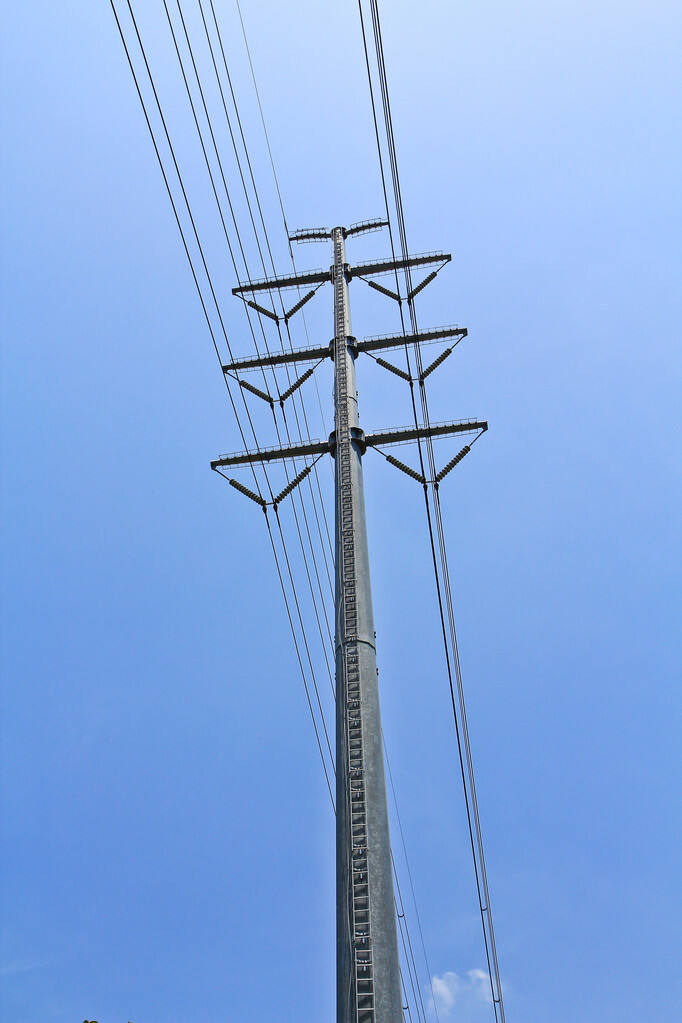

The black power pole incorporates state-of-the-art composite material technology that revolutionizes electrical infrastructure performance and longevity. This innovative construction utilizes high-strength polymer matrices reinforced with advanced fiber systems, creating a structural foundation that surpasses traditional materials in multiple performance categories. The composite materials provide exceptional resistance to environmental degradation, including UV radiation exposure, chemical corrosion, moisture penetration, and thermal cycling stress. Unlike conventional wooden or metal poles that deteriorate over time, the black power pole maintains its structural integrity and mechanical properties throughout its extended service life. The advanced manufacturing process involves precise control of fiber orientation and resin distribution, ensuring optimal strength-to-weight ratios and consistent quality across every black power pole produced. These materials exhibit superior fatigue resistance, withstanding repeated loading cycles without developing stress fractures or structural weaknesses. The non-conductive nature of the composite materials eliminates electrical conductivity concerns, enhancing safety for maintenance personnel and reducing the need for additional insulation systems. Thermal expansion coefficients are carefully engineered to minimize dimensional changes across temperature extremes, preventing joint failures and maintaining secure connections with electrical equipment. The black power pole composite construction resists impact damage from debris, vehicles, and extreme weather events, providing reliable service even in harsh operating environments. Chemical resistance properties protect against acid rain, salt spray, and industrial pollutants that typically cause rapid deterioration in traditional materials. The manufacturing process incorporates quality control measures that monitor fiber alignment, resin curing, and surface finish to ensure each black power pole meets rigorous performance standards. Advanced testing protocols verify mechanical properties, electrical characteristics, and environmental resistance before product release, guaranteeing consistent quality and reliability for infrastructure applications.